Shandong Tailai Petroleum Technology Co., Ltd

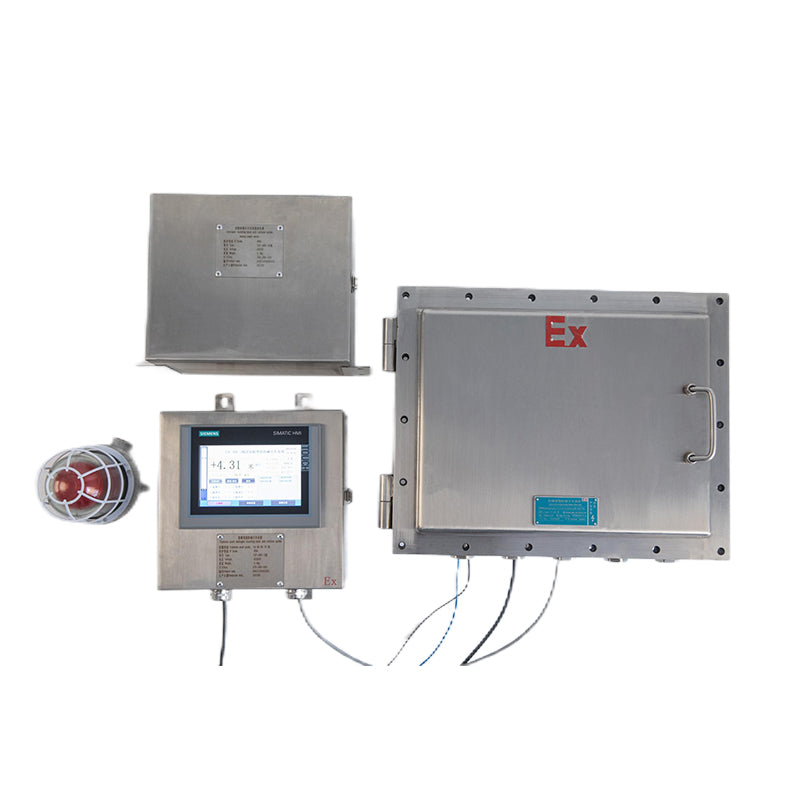

Integrated security monitoring and IoT remote transmission system

Integrated security monitoring and IoT remote transmission system

Couldn't load pickup availability

Before placing an order, please contact the merchant's email at :380549327@qq.com

The comprehensive safety monitoring and IoT remote transmission system is a new generation of intelligent comprehensive safety control system specially equipped for drilling rigs, workover rigs, pumping machines, oil tankers and other operational equipment. It is divided into on-site use versions and IoT remote monitoring versions. The function is to monitor the parameters of various sub equipment in the entire vehicle, and execute safety warnings and safety braking. The system is responsive, reliable, and easy to operate, greatly improving work safety, reducing labor intensity for workers, facilitating real-time monitoring of work by management personnel, improving economic benefits and management efficiency, and reducing safety hazards.

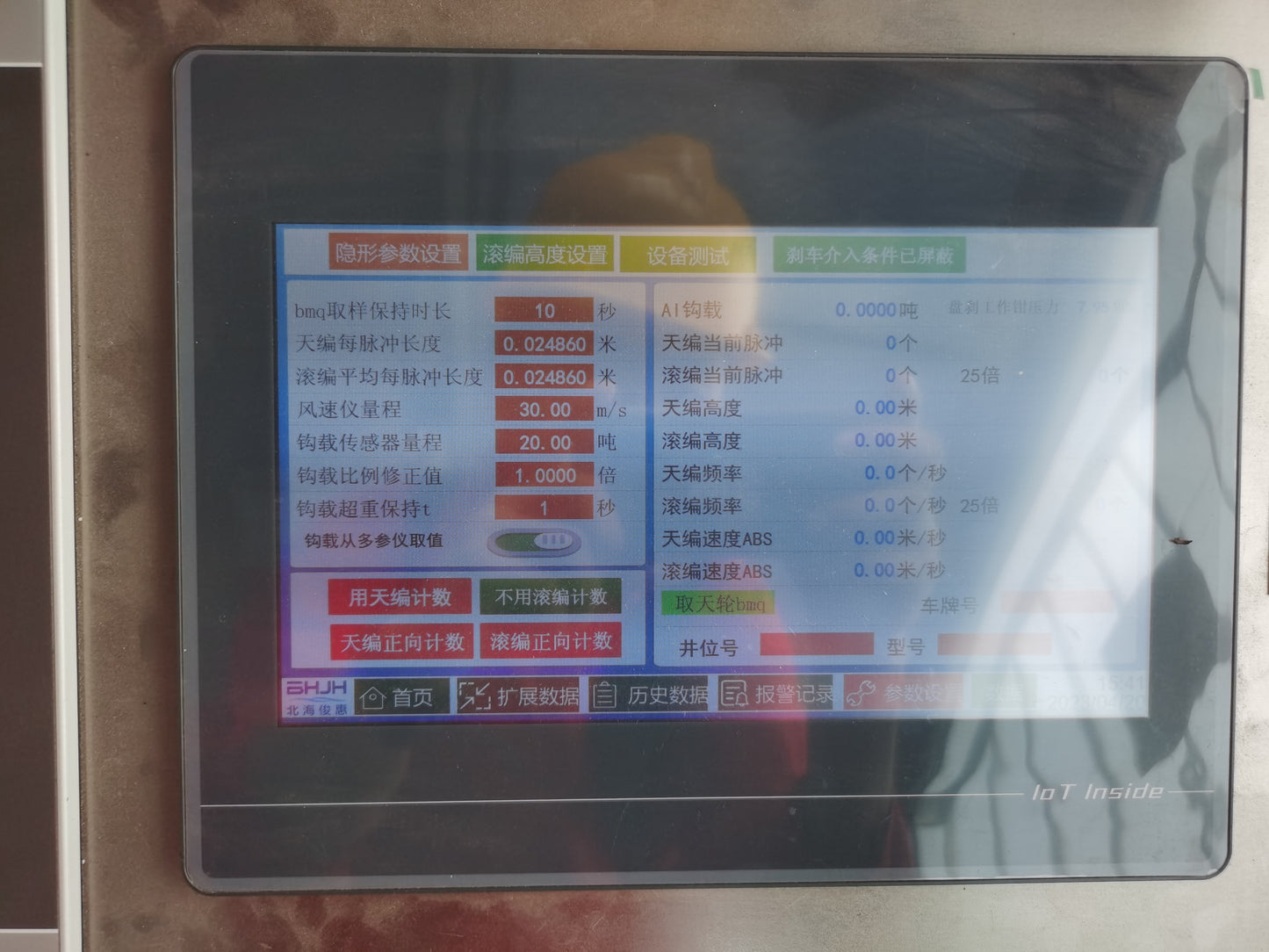

Real time and comprehensive monitoring of various parameters of the drilling and repair machine, including but not limited to: traveling block height, speed, hook load, drilling pressure, riser pressure, turntable torque, turntable speed, tong torque, pump stroke, mud level, mud backflow, mud density, hydraulic system and disc brake system hydraulic oil quality, oil pressure, oil temperature, air pressure, engine/motor speed, oil pressure, water temperature, oil consumption, oil quantity, battery life, frequency converter parameters, horizontal tilt angle, wind speed, wellhead safety lock pin screen, pneumatic support in place signal, auxiliary brake water temperature, flow rate, water pressure, air pressure, wire rope kilonewton meters, equipment operating time, operating efficiency and other system parameters, as well as various system parameters. Restrict setting parameters.

Various parameter safety warnings (sound and light), automatic control disc brakes, auxiliary brakes, cylinder deceleration brakes, emergency brakes, anti collision and anti impact (stuttering), soft landing, automatic memory, overpressure overflow, manual brake judgment, automatic brake intervention and other diversified functions;

All parameters and functions are adjustable, and password permissions can be set;

All parameters can be transmitted remotely and can be easily communicated, integrated, and safely interlocked with automated drilling and repair equipment.

Main technical parameters:

1. Working power supply: 50W DC24V

2. Working temperature: - 20 ℃ ~ + 50 ℃

3. Height measurement accuracy of traveling block: 0.02M

4. Braking control accuracy of traveling block: 0.1M

5. Hook load measurement accuracy: 0.1%

6. Horizontal inclination measurement accuracy: 0.01 °

7. Wind speed measurement accuracy: 2%

8. Oil pressure measurement accuracy: 0.1MPa

9. Alarm volume: > 60dB

10. Response time of service brake: < 0.1s

11. Display and remote transmission parameters: traveling block height, speed, hook load, Ton·Kilometer (KN·M), winch power, horizontal angle, wind speed and wind level, disc brake system pressure, auxiliary brake water temperature, water pressure, air pressure, equipment operation time, engine speed, oil pressure, water temperature, fuel consumption, fuel quantity, endurance time, motor speed, current, voltage, torque, frequency, power, energy consumption, transmission / frequency converter parameters, power battery power, battery BMS parameters The rotary table torque, rotary table speed, number of lifting and lowering pipe rods, various setting parameters and alarm information can be viewed through the computer and mobile phone, and the data of more than one year can be checked and traced.

12. Installation method: can be inlaid on driller's console or hung outdoors

Share